The Flat Flex Conveyor Belt, a product of precision engineering by Hebei Qijie Wire Mesh MFG Co., Ltd., exemplifies exceptional performance in industrial applications. Recommended for its reliability, efficiency, and versatility, its design and materials guarantee optimal functionality in various industries. It’s an excellent investment for boosting productivity and streamlining processes.

Materials

The Flat Flex Conveyor Belt is made from high-quality materials, primarily stainless steel, known for its durability, strength, and corrosion resistance. It also offers other alloys to meet specific requirements, including carbon steel for affordability and strength, galvanized steel for enhanced corrosion resistance, and specialized alloys for extreme temperatures or chemical exposure. The material choice varies according to the application; for example, food processing uses non-toxic, food-grade stainless steel for safety, while heat treatment processes utilize heat-resistant alloys.

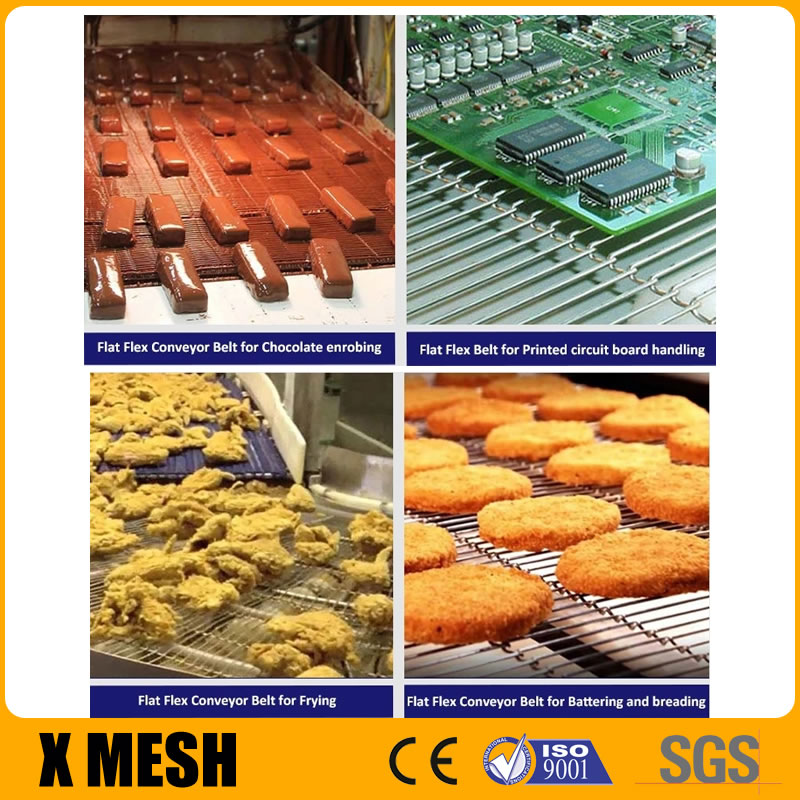

Applications of the Flat Flex Conveyor Belt

- Food Processing

Baking, Frying, and Cooling: Ideal for different stages in food preparation, ensuring hygiene and efficiency.

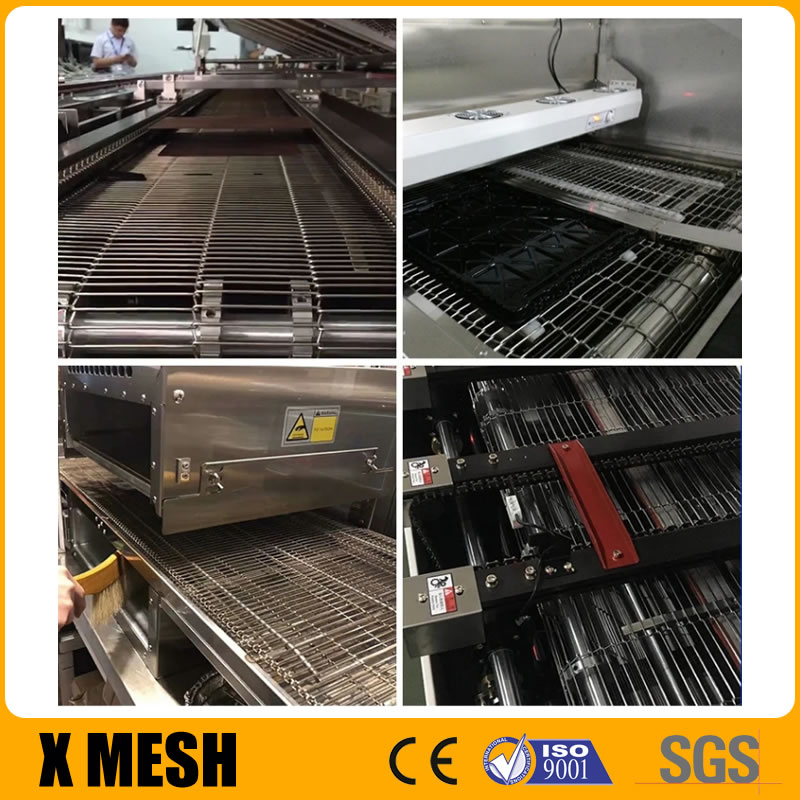

Freezing: Suitable for cold environments, maintaining performance under low temperatures. - Electronics Industry

Component Handling: Used for delicate handling and precise positioning of electronic components. - Packaging Industry

Product Transport: Facilitates smooth transport and handling of various packaged goods. - Automotive Sector

Assembly Lines: Integral in automotive assembly and parts handling, aiding in efficient production processes. - Metalworking

Heavy-Duty Use: Endures high loads and abrasive conditions, perfect for metalworking applications. - Pharmaceutical Industry

Medication Handling: Plays a critical role in the processing and handling of medications, where cleanliness and precision are essential. - Textile Manufacturing

Fabric Handling: Assists in the handling and transport of fabrics and fibers. - Glass and Ceramics Manufacturing

High-Temperature Operations: Withstands high temperatures, ideal for the transport of delicate glass and ceramic items. - Chemical Industry

Chemical Resistance: Offers reliable transport solutions in environments with chemical exposure. - Logistics and Distribution

Sorting and Movement: Enhances operational productivity in sorting and moving goods in logistics and distribution centers.

Features and Advantages of the Flat Flex Conveyor Belt

- High Flexibility for Tight Transfers

Tight Transfer Capabilities: Its flexible design allows for smooth transitions and tight transfers between conveyor systems, reducing product damage and loss.

Contour Adaptability: Easily conforms to various conveyor shapes and angles, enhancing versatility in layout design. - Easy to Clean, Supporting Hygiene Standards

Hygienic Design: The open mesh design allows for thorough cleaning, making it ideal for industries where hygiene is paramount, like food processing.

Reduced Downtime for Cleaning: Its ease of cleaning translates to less downtime, maintaining consistent production flow. - Robust Construction Ensuring Longevity

Durable Material Choice: Made from materials like stainless steel, it withstands harsh industrial environments, contributing to a longer lifespan.

Resistance to Wear and Tear: Engineered to resist the typical wear and tear of industrial use, ensuring sustained performance over time. - Minimal Maintenance Requirements

Low Maintenance Design: Requires minimal upkeep due to its robust construction, reducing maintenance costs and effort.

Ease of Repair: In the event of damage, sections of the belt can be easily repaired or replaced, avoiding the need for complete belt replacement. - Excellent Airflow and Drainage Properties

Optimal Air Circulation: The mesh design ensures excellent airflow, crucial for processes like drying and cooling.

Effective Drainage: Allows for effective drainage of liquids, beneficial in wet processing applications. - Additional Advantages

Customization Options: Available in various sizes and specifications, tailored to meet specific industry needs.

Temperature Resistance: Suitable for operations involving extreme temperatures, both high and low.

Load Carrying Capacity: Engineered to handle different weights, suitable for both lightweight and heavy-duty applications.

Chemical Resistance: Capable of withstanding exposure to various chemicals, making it suitable for the chemical industry.

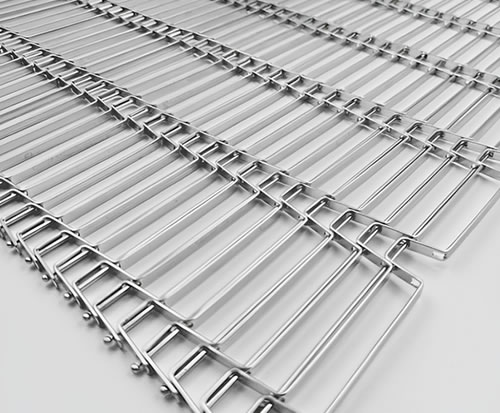

Flat Flex Conveyor Belt Edge Types

- Clinched Edges are commonly used for their smoothness, preventing snagging, especially where belts interact with other parts. Often have a turned diameter of about 5 mm to 10 mm.

- Welded Edges, where edges are welded to links, offer strength for heavy-duty or high-tension applications. Weld spots can be around 1 mm to 3 mm in diameter.

- Knuckled Edges, with looped edge wires, are suitable for light loads and safe interaction with workers. Loop diameters typically range from 3 mm to 8 mm.

- Chain Link Edges add strength and stability, ideal for heavy loads and improved belt tracking. Chain link sizes can vary based on belt and load requirements.

Specifications

- Wire Diameter: Typically ranges from 0.9 mm to 3 mm, with finer diameters for light applications and thicker for heavy-duty use.

- Mesh Size/Pitch: The spacing between wire spirals can vary, common values include 4 mm, 5 mm, 10 mm, up to 20 mm or more for larger items.

- Belt Width: Available in a wide range, from narrow belts of about 100 mm to wider ones over 3000 mm, suited for different conveyor systems.

- Materials: Stainless steel wire diameters are often in the range of 0.9 mm to 3 mm. Other materials like carbon steel have similar or slightly varied dimensions.

- Load Capacity: Determined by wire diameter and mesh size; thicker wires and tighter meshes support heavier loads.

- Operating Temperature Range: Specific to material, stainless steel belts can typically withstand temperatures from -30°C to 400°C.

- Tensile Strength: Depends on material and wire diameter; higher tensile strength for thicker wires.

- Flexibility: The radius of the smallest pulley the belt can navigate is typically a few times the belt’s pitch.

- Ease of Maintenance: Modular designs allow for easy replacement of damaged sections, dimensions of repair pieces depend on original belt specs.

- Airflow and Drainage: Mesh openings can range from small (about 1 mm²) to large (over 400 mm²) for different applications.

Qijie Company meets a wide range of customer needs with our advanced equipment and expert engineers, ensuring customization of product specifications, including widths, lengths, and mesh sizes. Our services are available 24/7 to cater to your specific requirements, including special custom edges designed for unique system needs, such as reinforced edges or distinct shapes for particular applications. Please don’t hesitate to contact us for tailored solutions.

See pictures for examples

Qijie Model FFCB-001 Flat Flex Conveyor Belt

Qijie Model FFCB-002 Flat Flex Conveyor Belt