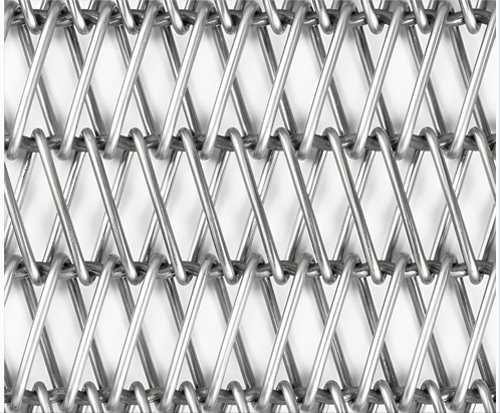

Balanced Weave Conveyor Belts by Hebei Qijie Wire Mesh MFG Co., Ltd. are a versatile and robust solution in the conveyor belt industry. These belts, known for their left and right-hand wound spirals connected by crimped cross wires, cater to a vast range of industrial applications. Their design includes alternating wire mesh spirals, available in both single and double spiral formations, linked by either crimped or straight cross wires. This construction allows for a diverse selection of mesh sizes, making these belts suitable for a variety of uses.

Renowned for their efficient tracking and stability, Hebei Qijie’s Balanced Weave Conveyor Belts prevent lateral drift and minimize movement thanks to their crimped cross rods. The company also offers the Straight Running Friction Driven Belts, drum-driven alternatives to standard sprocket-driven belts. This range spans from simple weaves to complex, tightly-woven designs, providing extensive customization in terms of materials and patterns.

For specific applications, customers can choose from three driving methods: positive drive, friction drive, and chain drive, each offering unique benefits.

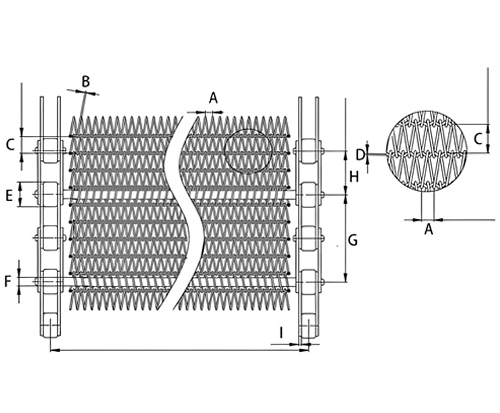

Balanced Woven Belt Chain Edge with Chain Edge

A: Spiral Wire Pitch (mm)

B: Spiral Wire Diameter (mm)

C: Cross Rod Pitch (mm)

D: Cross Wire Diameter (mm)

E: Roller Diameter (mm)

F: Support Rod Diameter (mm)

G: Support Rod Pitch (mm)

H: Chain Pitch (mm)

I: Plate Thickness (mm)

Specification

Our Balanced Weave Conveyor Belts are designed to meet a variety of industrial needs, offering customization in size, temperature endurance, and material.

General Specifications:

- Belt Width Options: Ranging from 200 mm to 5,000 mm.

- Maximum Belt Width: Up to 160 inches (4060mm).

- Operational Speed: Capable of reaching up to 1000 feet per minute (304.8 meters per minute).

- Temperature Endurance: Up to 2100°F (1149°C), varying based on material.

- Features: Knuckled salvage edges for added durability.

Specific Wire and Rod Specifications:

- Wire Diameters: Range from 1.2 mm to 3 mm.

- Cross Wire Diameter: 1.2 mm to 4.0 mm.

- Flat Wire Size: 1.0 mm × 0.7 mm to 6.0 mm × 3.0 mm.

- Spiral Wire Pitch: Options include 4, 5, 6, 8, 11, 15, 22 mm.

- Cross Rod Pitch: Variety ranging from 4 mm to 33 mm, including 4, 5, 6, 6.4, 8, 10, 12, 13, 15, 20, 23, 25, 27 mm.

- Spiral Wire Diameter: Ranges from 0.9 mm to 3.0 mm, with specific ranges including 0.9 to 1.2 mm, 0.9 to 1.6 mm, 1.2 to 2.0 mm, 1.6 to 3.0 mm.

- Cross Wire Diameter: Varies from 1.2 mm to 4.0 mm, with specific ranges like 1.2 to 1.6 mm, 1.2 to 2.5 mm, 1.6 to 3.0 mm, 2.0 to 4.0 mm.

These comprehensive specifications showcase the adaptability and versatility of our Balanced Weave Conveyor Belts, suitable for a wide range of industrial applications.

Belt Types:

- Standard Balanced Spiral Woven Belt: Alternating left and right-hand coils connected by crimped cross wire.

- Double Balanced Spiral Woven Belt: Similar to the standard type but with paired intermeshing coils connected by crimped cross wire, suitable for smaller products.

- Standard Balanced Spiral Woven Belt with Straight Cross Wire: Similar to the standard type but with straight cross wire connecting single interlocking coils.

- Double Balanced Spiral Woven Belt with Straight Cross Wire: Builds upon the double balanced spiral design, using straight cross wire with double intermeshing coils for small product handling.

Edge Finishes:

- Welded Edge: Common, cost-effective, welding coil and crimp wires together.

- Laddered Edge: Offers smoothness and flexibility, suitable for high-temperature applications and larger crimp wire pitches.

- Hook Edge: Similar to laddered edge, providing smoothness and flexibility for larger crimp wire pitches.

- Chain Edge Driven Mesh: Adaptable with side chains connected via cross rods through mesh coils and chains at the edges, offering an alternative driving method.

Materials

Our conveyor belts are constructed from premium stainless steel, offering a variety of options to suit different industrial requirements. The available materials include:

- Stainless Steel Variants:

T316LSS: Known for its resistance to corrosion and pitting.

T304SS: Popular for its durability and resistance to a wide range of temperatures and chemicals.

T430SS: Recognized for its magnetic properties and good corrosion resistance. - Alternative Materials:

High Carbon Steel (HCS): Valued for its strength and durability, ideal for heavy-duty applications.

Galvanized Wire: Offers additional corrosion resistance, suitable for various environmental conditions. - Additional Stainless Steel Options:

SS 201: Known for its lower nickel content and higher manganese and nitrogen content.

SS 304: A common form of stainless steel, known for its excellent corrosion resistance.

SS 316: Contains molybdenum for enhanced corrosion resistance.

SS 314: Ideal for high-temperature applications due to its superior heat resistance. - Wear-Resistant Stainless Steel (WRSS): Specially designed for environments where abrasion and wear are a concern.

- Galvanized Steel (Galv): Provides robust protection against corrosion and is often used in outdoor or harsh environments.

These material options ensure that our conveyor belts can be tailored to meet the specific demands of various industrial applications, from food processing to heavy manufacturing, ensuring reliability and longevity.

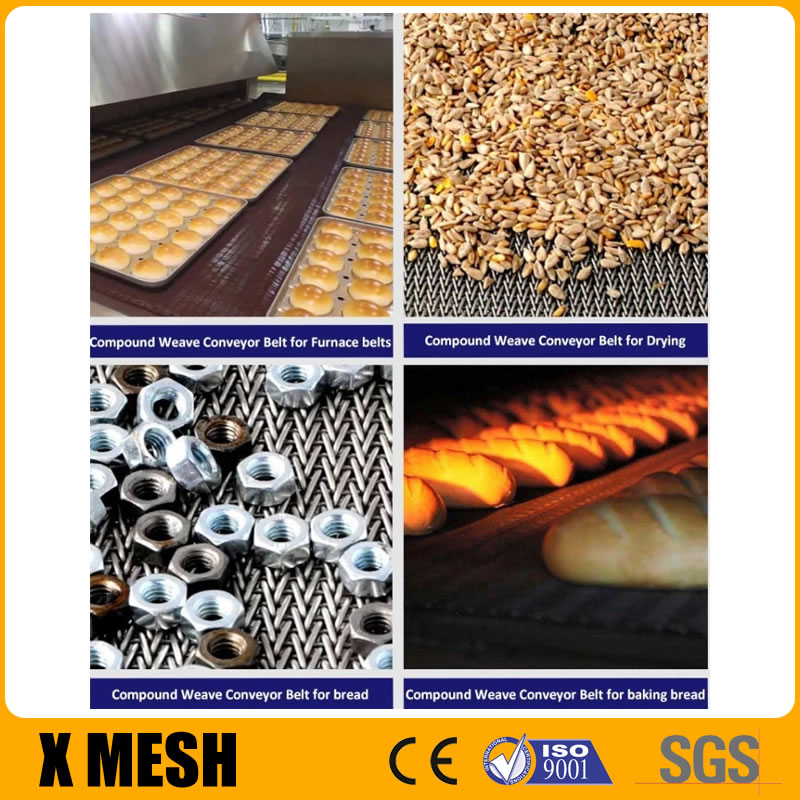

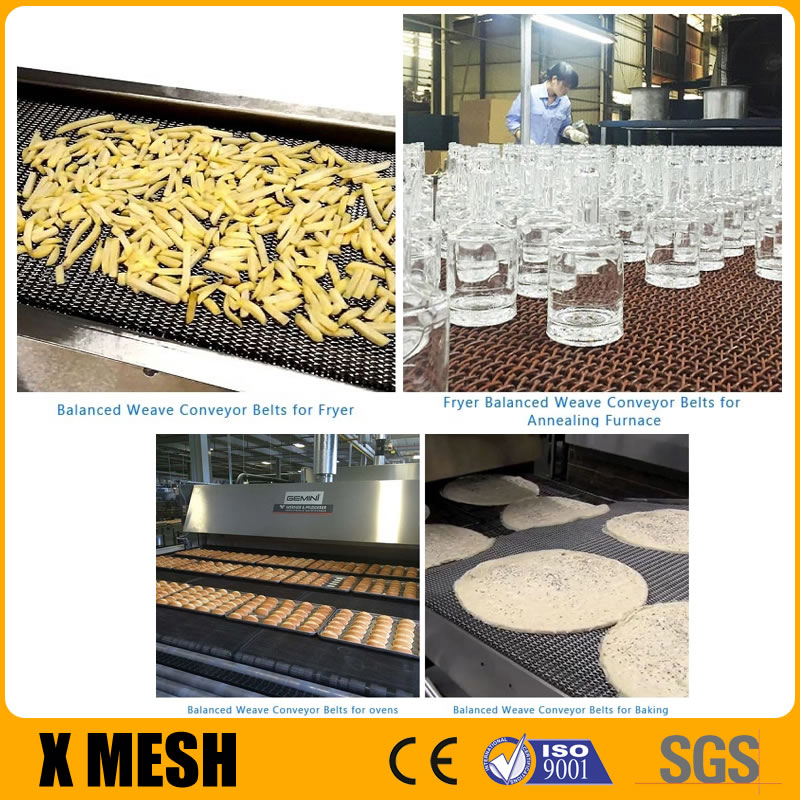

Key areas of application

Our Balanced Weave Conveyor Belt is renowned for its versatility, playing a crucial role in various industries owing to its adaptability and durability. It serves as a valuable asset across a wide spectrum of industrial applications, ensuring efficient and reliable operations.

- Food Processing: Ideal for various stages of food production including baking, frying, drying, and cooling. Its materials and design are suitable for handling food items safely and efficiently.

- Metallurgical Processes: These belts are capable of withstanding the harsh environments of metal processing, including high temperatures and heavy loads.

- Glass and Ceramic Industry: Their durability and temperature resistance make them suitable for the production and handling of glass and ceramic products.

- Chemical Handling: The belts’ construction materials are resistant to various chemicals, making them suitable for use in chemical processing and transportation.

- Decorative Applications: Beyond industrial uses, these belts can also be utilized in decorative settings, showcasing their versatility in both functional and aesthetic roles.

Advantages

- Versatility: Adaptable to a wide range of applications with varying load and temperature conditions.

- Durability: Made with high-quality materials, ensuring longevity and resistance to wear and tear.

- Stability and Tracking: Excellent tracking properties prevent lateral movement, ensuring smooth operation.

- Customizability: Available in various materials, weaves, and specifications, including options for edge plates and flights.

- Compliance with Standards: Manufactured in compliance with food safety standards like FDA and GMP.

- Ease of Maintenance: Simple structure facilitates easy repairs and maintenance.

- Heat and Corrosion Resistance: Suitable for high-temperature environments and resistant to chemical, acid, and alkaline.

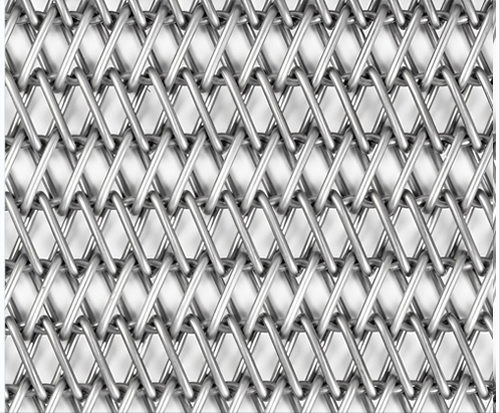

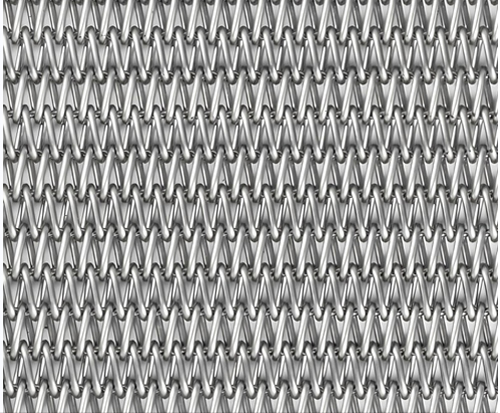

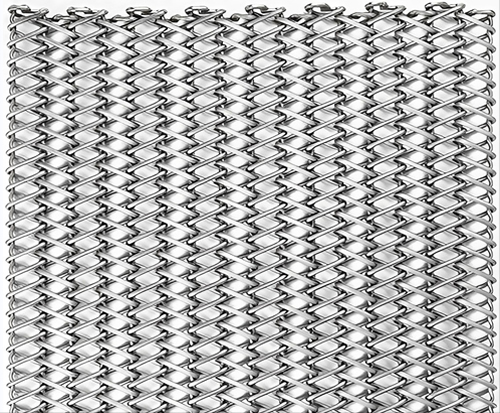

See pictures for examples

Qijie Model BWCB-001 Balanced Weave Conveyor Belt

Qijie Model BWCB-002 Balanced Weave Conveyor Belt

Qijie Model BWCB-003 Balanced Weave Conveyor Belt

Qijie Model BWCB-004 Balanced Weave Conveyor Belt