As a leading manufacturer and exporter, Hebei Qijie Wire Mesh MFG Co., Ltd. offers Compound Weave Conveyor Belts, a revolutionary product in industrial conveyance. Committed to innovation and quality, we develop these belts to meet diverse industrial needs. Our competitively priced Compound Weave Conveyor Belts showcase our expertise in delivering precision, durability, and versatility, setting industry benchmarks.

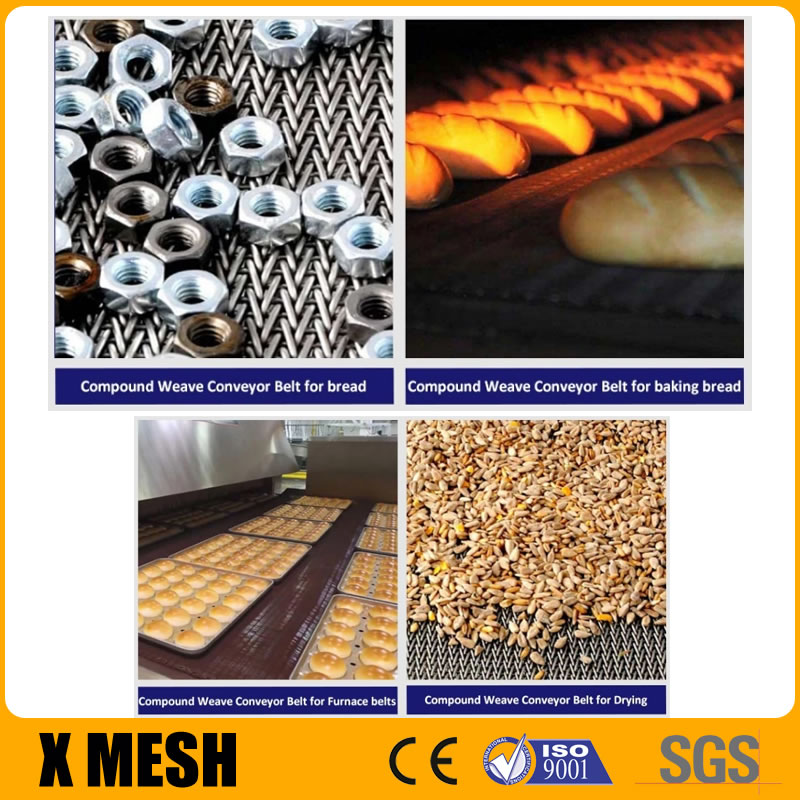

The Compound Weave Conveyor Belt, also known as the stainless steel Cordweave, Compound Balanced Woven Belt, V-shaped, or Baking Band Conveyor Belt, is uniquely designed with right- and left-hand spirals connected by straight cross rods. This design results in a high-density, flat-surfaced belt with small openings, perfect for transporting tiny items and uniform heat distribution, making it ideal for tasks like biscuit baking and sorting small mechanical parts.

The Compound Weave Conveyor Belt, similar in structure to the balanced weave conveyor belt, boasts a tighter mesh that results in a high-density and high-strength surface. This design makes it especially effective for conveying small products such as nuts, bolts, screws, and nails. Its closely woven mesh and durable material composition render it perfect for applications that demand both precision and durability.

Featuring a Compound Balanced Weave, the belt’s tight mesh enhances tracking and baking efficiency. Its smooth, dense weave, offered in various sizes, is ideally suited for bakery applications, providing an optimal surface area for diverse requirements. This combination of a tight weave and versatile sizing makes the belt an excellent choice for a wide array of needs where efficiency and reliability are crucial.

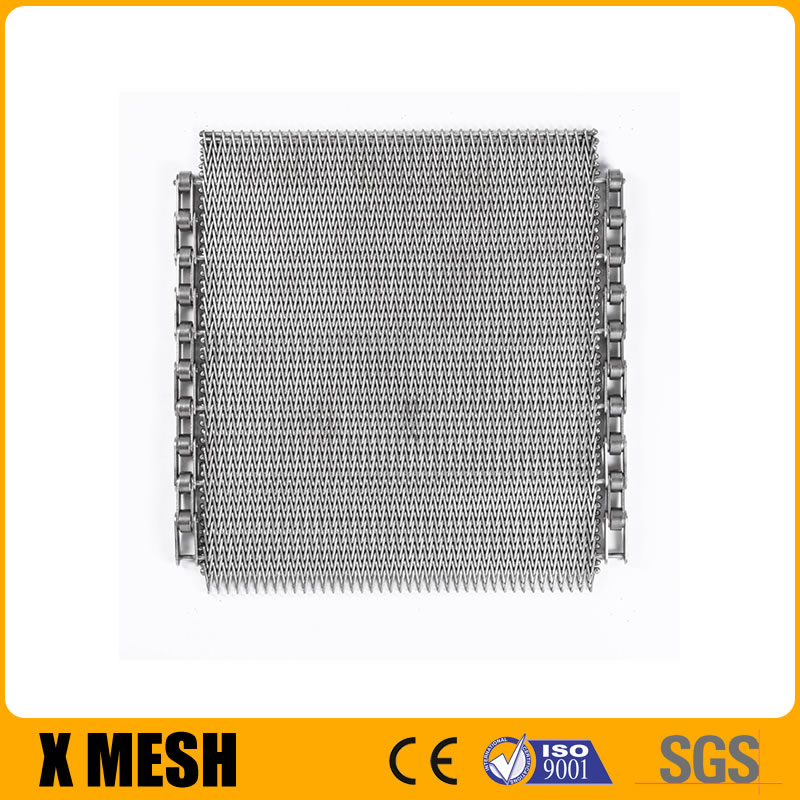

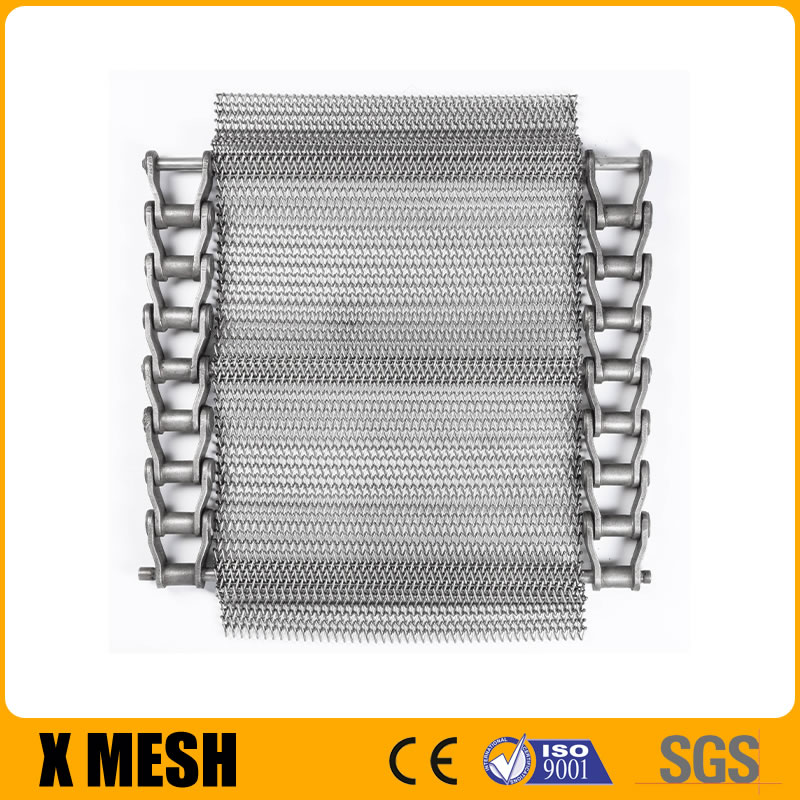

Compound Conveyor belts offer two edge options:

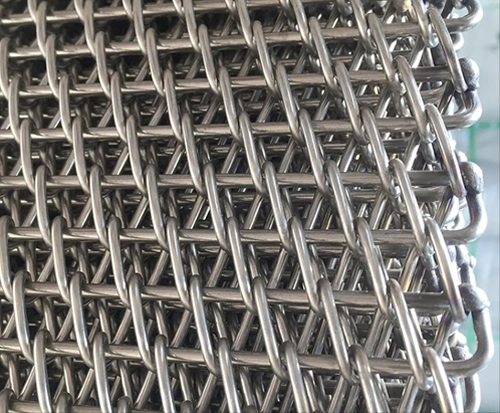

- Welded Edge: Ensures a robust and solid boundary, ideal for heavy-duty applications.

- Chain Edge: Provides added flexibility and strength, suitable for various conveying requirements.

Compound Weave Conveyor Belt offered in two spiral wire styles:

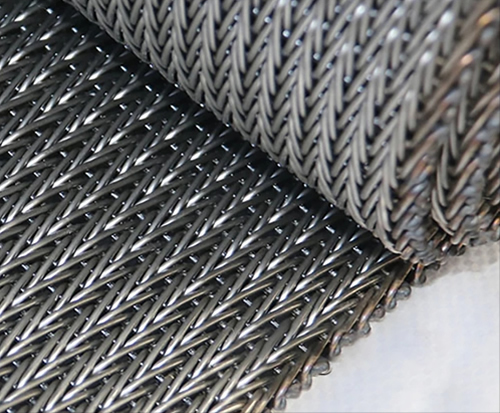

They are available in both flat and round wire versions, provides a stark contrast to the flat flex conveyor belt. Its tightly woven, flat mesh design makes it particularly effective for conveying small items. Constructed from stainless steel and high carbon steel, the belt boasts excellent resistance to high temperatures and high tensile strength, ensuring both durability and an extended lifespan.

- Round Spiral Wire: Ideal for general conveying purposes.

- Flat Spiral Wire: Better suited for operations requiring a smoother process and the handling of finer products.

This adaptability and customization make the Compound Weave Conveyor Belt a versatile solution for various conveying needs.

Compound Weave Conveyor Belt features two baffle designs

To further enhance performance and minimize product loss, the belt features two baffle designs:

- Metal Baffles: Added to provide extra stability and prevent items from slipping off.

- Foldable Baffles: Offer the versatility to create barriers directly on the belt, adapting to different conveying scenarios.

These features make the compound weave conveyor belt a versatile choice for a wide range of industrial applications.

Versatility in Material Choice

Compound Weave Conveyor Belts are constructed from materials chosen for their strength, durability, and industry-specific benefits:

- Stainless Steel (Grades 304/316): Commonly used due to its durability, corrosion resistance, and high-temperature endurance. These grades are ideal for the food industry, offering a balance of strength and hygiene.

- Stainless Steel (Grades 310S/314): Known for superior high-temperature and oxidation resistance, making them suitable for heat treatment applications.

- High Carbon Steel: Chosen for its exceptional strength and durability. High carbon steel belts are used in environments requiring high tensile strength, resistance to wear, and suitability for high-temperature and heavy-duty tasks.

These materials ensure that Compound Weave Conveyor Belts are robust and versatile, meeting the demands of various industrial applications, including food processing, baking, heat treatment, and conveying small items like nuts and bolts.

Features

- Tightly Woven Mesh: The belt’s design includes closely interlinked right- and left-hand spirals, connected by straight cross rods, creating a tight, flat mesh. This structure is ideal for conveying small, delicate items that might otherwise slip through more open weave belts.

- High-Density Surface: The close mesh design results in a high-density surface, providing a smooth and flat conveying area that ensures stable movement of products.

- Uniform Heat Distribution: The dense weave of the belt facilitates uniform heat transfer, making it particularly suitable for baking and cooking applications where consistent heat application is crucial.

- Durability and Strength: Constructed from materials that offer high tensile strength and resistance to wear, tear, and corrosion, ensuring longevity and reliability.

- Optional Baffles: Includes options for metal baffles or foldable baffles to prevent products from falling off, enhancing the belt’s functionality in various conveying scenarios.

- Adaptability: Suitable for a range of applications, including food processing, baking, heat treatment, and handling small mechanical components like nuts, bolts, and screws.

- High-Temperature Environments: The 314 stainless steel variant withstands temperatures up to 1000-1500 °C, making it ideal for challenging environments like powder metallurgy furnaces.

Applications

- Food Processing and Baking: Ideal for the food industry, especially in baking processes like biscuit and cracker production, due to their uniform heat distribution and hygiene-friendly materials.

- Heat Treatment Processes: Used in heat treatment facilities because of their high-temperature resistance, especially belts made from high-grade stainless steel.

- Conveying Small Items: Effective in transporting small, delicate items such as nuts, bolts, screws, and nails, thanks to their tightly woven mesh that prevents items from slipping through.

- Pharmaceutical Industry: Utilized for the controlled movement and handling of small components, often in clean environments.

- Furnace Operations: Employed as furnace curtains or in operations involving furnaces, owing to their ability to withstand high temperatures and maintain structural integrity.

- Packaging Industries: Used for the smooth conveyance of packaged goods, ensuring stability and efficient handling.

- Sorting and Handling Operations: Their flat and stable surface makes them suitable for sorting and handling small mechanical components.

- Chemical Processing: Due to their corrosion-resistant materials, these belts are suitable for use in chemical processing plants where exposure to harsh chemicals is common.

Specifications of the Compound Weave Conveyor Belt

- Basic Specifications:

Wire Type: Available in both round wire and flat wire options.

Edge Type: Options include welded or chain edges.

Maximum Belt Widths: Up to 160 inches (4600mm), accommodating a broad range of industrial applications.

Speeds: Capable of operating at speeds up to 1000 feet per minute (304.8 meters per minute).

Temperature Tolerance: Can withstand temperatures up to 1000°F (538°C), making it suitable for high-temperature environments. - Dimensional Specifications:

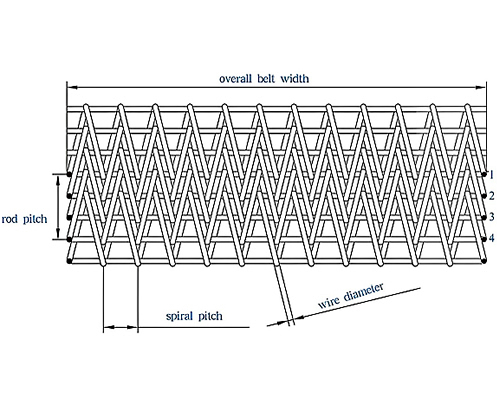

Pitch of Spiral Wires: Ranging from 6mm to 20mm.

Pitch of Cross Rods: Also between 6mm to 20mm.

Wire Diameter: Options include 1.2 mm, 1.4 mm, 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, and 3 mm.

Belt Width: Customizable from 200 mm to 3,000 mm.

Diameter of Cross Wire: Varying from 0.9 mm to 2.6 mm.

Cross Rod Number per Pitch: Available as 3, 4, 5, or 6, based on request.

Temperature Range: Designed to operate in a range from -50 °C to 1,150 °C. - Coil and Wire Details:

Coil Pitch (mm): Available in sizes of 5.08, 11.29, 10.16, 4.24, 8.47, 6.35, and 8.71.

Coil Wire Diameter (mm): Includes 1.22, 2.03, 0.91, 1.63, and 1.6 × 1.3 among others.

Cross Wire Pitch (mm): Options like 3.05, 4.35, 5.08, 2.24, 3.63, 2.82, and 3.9.

Cross Wire Diameter (mm): Ranges from 1.22 to 2.64, with variants like 1.63.

Number of Cross Wires per Coil (mm): Available in counts of 3, 4, and 5.

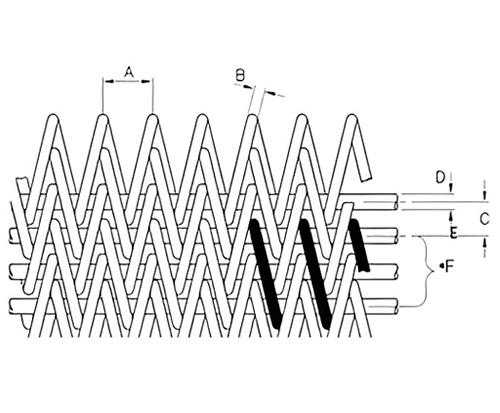

A: Coil Pitch (mm)

B: Coil Wire Diameter (rnm)

C: Cross Wire Pitch (mm)

D: Cross Wire Diameter (rnrn)

E: Number of Cross Wires per Spiral Coil (mm)

F: Example show 3 cross wires per spiral coil— “cordweave 3″

Pitch of Spiral Wires: Ranging from 6mm to 20mm.

Pitch of Cross Rods: Also between 6mm to 20mm.

Belt Width: Customizable from 200 mm to 3,000 mm.

Wire Diameter: Options include 1.2 mm, 1.4 mm, 1.5 mm,

1.6 mm, 1.8 mm, 2 mm, 2.5 mm, and 3 mm.

Compound Balanced Woven Belt, V-shaped

Chain Edge Compound Weave Conveyor Belt