Hebei Qijie Wire Mesh MFG Co., Ltd.’s Chain Link conveyor belt stands out in various industrial applications due to its simplicity, cost-effectiveness, versatility, and adaptability. Its broad applicability and customizable options make it an invaluable tool for enhancing productivity and effectiveness across numerous industries.

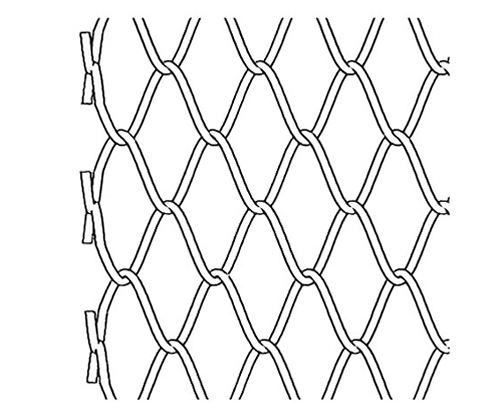

The Chain Link conveyor belt, known for its straightforward design, offers an economical and efficient solution for light-duty drying, cooling, and conveying applications. Made primarily of stainless steel wire mesh, it features interwoven spiral coils that form a chain-link-fence-like structure, providing a large open area ideal for energy-efficient processes.

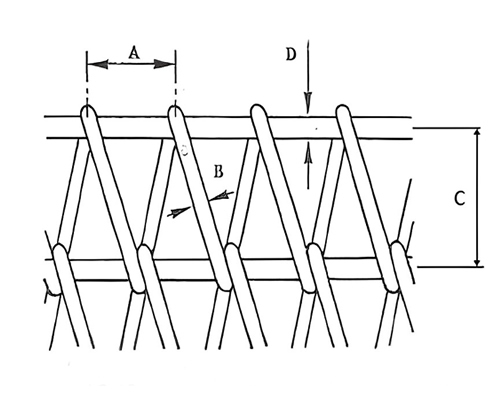

A: Lateral Coil Pitch (mm) B: Coil Wire Diameter (mm)

C: Longitudinal Cross Wire Pitch (mm) D: Cross Wire Diameter (mm)

Materials:

- Stainless Steel: The most common material used, known for its durability, corrosion resistance, and suitability for food processing and high-temperature applications. Different grades like 304, 316, and 201 are used depending on the specific requirements for corrosion resistance and strength.

- Mild Steel: A cost-effective option used in general-purpose applications. Mild steel belts often undergo surface treatments, such as galvanizing (electric or hot-dipped), to improve their durability and resistance to environmental factors.

- Carbon Steel: Offers good strength and is economical. It’s suitable for various applications where high-strength and lower costs are important.

These materials enable the Chain Link Conveyor Belts to operate effectively in different environments, from high-temperature furnaces to food processing lines, ensuring both durability and functionality. The choice of material largely depends on the specific requirements of the application, such as resistance to corrosion, strength, and exposure to high temperatures or chemicals.

Applications

Chain Link Conveyor Belts are widely used for their versatility, durability, and efficiency. They are particularly valued for their open mesh design, which promotes airflow, and their ability to withstand various environmental conditions.

- Food Processing and Baking: They are ideal for cooking, baking, and freezing applications due to their open mesh design that allows for efficient heat transfer and airflow. This is particularly useful in ovens, fryers, and other cooking and baking equipment.

- Chemical Industry: The corrosion-resistant properties of stainless steel Chain Link belts make them suitable for chemical processing environments where they may be exposed to aggressive substances.

- Cooling and Refrigeration: Their large open area makes them excellent for applications requiring airflow, such as in cooling systems and refrigeration units.

- Drying Processes: In drying ovens and similar applications, the belt facilitates efficient moisture evaporation and heat distribution, essential for drying processes.

- Annealing Furnaces: The heat-resistant nature of these belts makes them suitable for use in annealing furnaces, where controlled heating and cooling are critical.

- Pharmaceuticals and Cosmetics: Used in the production and packaging lines where cleanliness and resistance to various chemicals are important.

- Automotive and Electronics: For the assembly and transport of components, where precision and reliability are key.

- Packaging and Conveying: These belts are used in various packaging and conveying systems due to their adaptability and efficiency in handling different types of products.

- Waste Treatment and Recycling: Their durability makes them suitable for use in harsh environments like waste treatment and recycling facilities.

- Glass and Ceramics Industry: In applications where products must be transported through high-temperature zones.

Specifications

- Wire Diameter:

Ranges typically from 1.2 mm to 3 mm.

The diameter influences the belt’s strength and flexibility, with thicker wires offering greater load capacity. - Spiral Pitch (Distance between spirals):

Can vary from 6 mm to 40 mm.

Affects the open area of the belt and is crucial for applications requiring specific levels of airflow or particle size containment. - Rod Pitch (Distance between cross rods):

Generally ranges from 5 mm to 30 mm.

Determines the belt’s structural integrity and load-bearing capacity. - Belt Width:

Available from 200 mm up to 5,000 mm or more.

The width is chosen based on the application’s scale and the size of the products being transported. - Edge Types:

Welded, Knuckled, or Chain Edges, each offering different benefits in terms of strength, flexibility, and motion mechanism. - Mesh Size:

Varies depending on the spiral and rod pitches.

Determines the level of product support and the type of applications the belt is suited for. - Load Capacity:

Dependent on material, wire diameter, and overall belt construction.

Customizable to suit specific application requirements. - Temperature Resistance:

Varies with material choice; stainless steel options offer higher temperature resistance.

Main Edge Types

The choice of edge type plays a significant role in the functionality and suitability of the Chain Link Conveyor Belt for different applications. It affects factors like the belt’s strength, flexibility, the smoothness of operation, and the ability to handle various loads and operational stresses. The main edge types include:

- Welded Edge:

In this type, the coil wires at the belt edges are looped together and welded.

It provides a smooth finish and is the most common and economical edge finish.

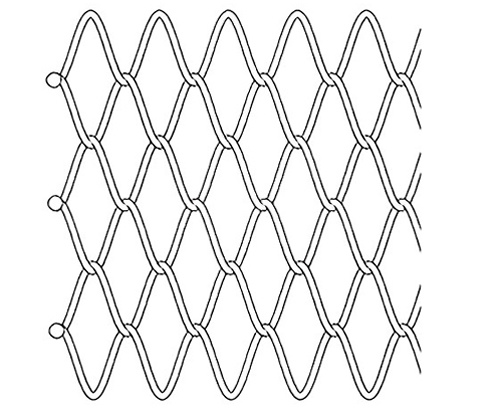

Suitable for applications where a strong, closed edge is required. - Knuckled Edge:

Here, the end of each coil wire is bent into a ‘U’ shape and interlocked with the adjacent coil.

This edge style offers enhanced flexibility and reduces stress at the belt edges.

It is a practical choice for less demanding applications, where a smooth edge is not crucial. - Chain Edge:

In addition to welded and knuckled edges, some Chain Link belts can be driven by side chains.

This involves cross rods located through the mesh coils and then connected to chains at the mesh edges.

This type of edge provides a different mechanism of motion and support, making it suitable for specific conveyor systems. - Reinforced Edges:

For additional strength, edges can be reinforced with a thicker wire or a special design.

This is ideal for heavier loads or more demanding conveying applications. - Special Custom Edges:

Depending on the application, custom edges can be designed to meet unique operational requirements.

This could include specific shapes, materials, or configurations tailored to a particular use.

Design Style:

Each design style of Chain Link Conveyor Belts offers specific benefits and is suitable for different types of applications, depending on factors like the load capacity, the need for airflow, the type of products being conveyed, and environmental conditions. The versatility in design allows these belts to be used across a broad range of industries, from food processing to industrial manufacturing.The key design styles include:

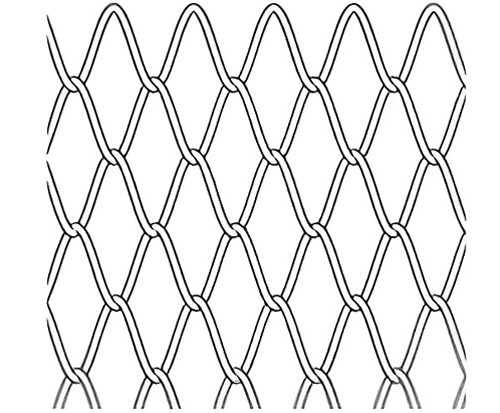

- Standard Chain Link Design:

This is the basic form, consisting of interwoven spiral wires.

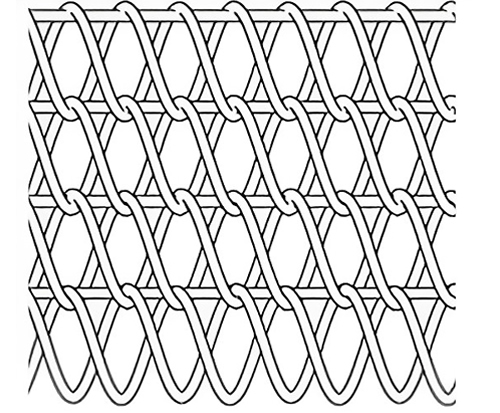

It’s ideal for applications where the emphasis is on maintaining an open area for efficient drying or cooling, and where the load is relatively light. - Rod Reinforced Chain Link Design:

This style includes cross rods that pass through the spiral wires, significantly enhancing the belt’s strength and stability.

It’s suitable for applications that require a balance between maintaining an open area and handling heavier loads. - Duplex Chain Link Design:

A more advanced version, the Duplex Link Belt features double interwoven spiral wires.

This design results in a smaller open area but provides greater strength and load-bearing capacity.

It’s ideal for processes that require both high load capacity and efficiency. - Balanced Weave Design:

While not a traditional chain link style, the balanced weave design is sometimes used in similar applications.

It involves alternating left and right-hand spiral coils, providing a balanced and stable conveying surface. - Flat Wire Chain Link Design:

Incorporates flat wire spirals for a more rigid and flat surface.

Suitable for conveying flat products or where a more stable conveying surface is required. - Compound Weave Design:

A combination of different weaving styles to create a more robust and tight mesh.

This design is used in applications requiring a small mesh opening with high strength. - Customized Designs:

Conveyor belts can also be custom-designed to meet specific requirements of an application.

This could include unique weaving patterns, wire sizes, materials, and edge treatments.

Features

Chain Link Conveyor Belts from Hebei Qijie Wire Mesh MFG Co., Ltd. offer several notable features that make them suitable for a wide range of industrial applications:

- Simplicity in Design: The straightforward structure of interwoven spiral coils creates an open mesh. This design is not only easy to manufacture and maintain but also highly effective for light-duty applications.

- Economical Solution: The simple construction of the Chain Link conveyor belt makes it a cost-effective option compared to other types of conveyor belts. Its lightweight nature further enhances its economic advantages, particularly in applications with low load requirements.

- Functional Versatility: While it excels in lightweight lifting and conveying tasks, its design also makes it functional for various applications. The large open area of the mesh is especially effective for processes requiring good airflow, such as drying and cooling.

- Customizable Edge Styles: The belt can be tailored with different edge styles – welded or knuckled, depending on specific application needs. Each style offers its own benefits in terms of strength and flexibility.

- Baffles Addition: Side and center baffles can be incorporated into the belt design. These are useful for preventing products from falling off and can assist in sorting and transporting materials.

- Chain Link Drive: The belt’s chain link drive pattern ensures smooth and efficient operation, contributing to overall productivity and minimal downtime.

- Durable Material Quality: Commonly made from Grade 304 Stainless Steel, the belt offers durability and resistance to corrosion. Other steel grades are available upon request.

- Rod Reinforced Option: For applications requiring higher load capacity, the belt can be reinforced with cross-rods, enhancing its strength and load-bearing capabilities.

- Alternate Panel Orientation: To address tracking issues, the belt can be supplied with alternating left and right-facing panels.

These features collectively make the Chain Link conveyor belt a versatile and efficient choice for various industries, capable of meeting diverse conveying needs while ensuring reliability and effectiveness.

See pictures for examples

Chain Link Belt Without Rod Reinforced

Chain Duplex Link Belt With Rod Reinforce

Welded Edge

Knuckled Edge